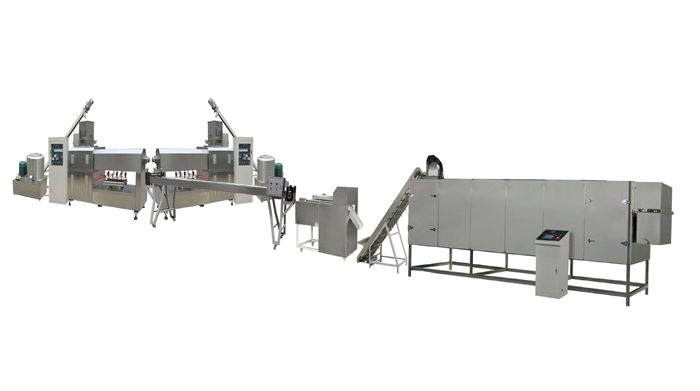

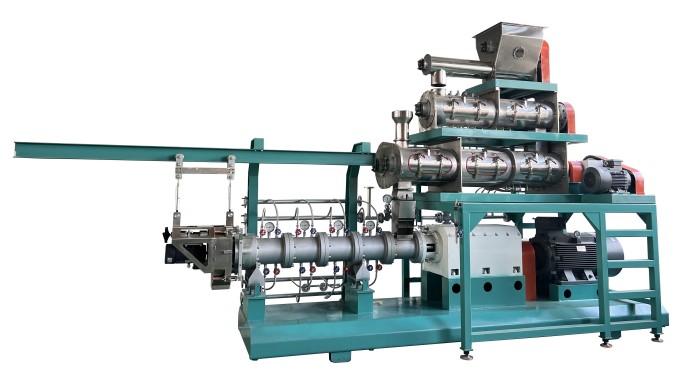

1.Features of twin screw extruder

The biggest feature of the twin-screw extruder is that it can process various raw materials without considering the composition of the raw materials. Diverse components like grains, soy flour, animal flour, fresh meat, fats, nutrients, proteins, vitamins, starches, etc. can be easily processed.

There are many kinds of feeds can be processed by twin-screw extruder, which can adapt to the processing of high-viscosity materials, low-viscosity materials or high-moisture and high-fat formula products. In terms of aquatic feed, fish and shrimp feed, as well as river eel and ornamental fish feed, all can be producted by twin screw extruder. Especially for granular aquatic feed (0.5-1.5 mm in diameter), high-fat aquatic feed and formula not fixed feed must be produced by a twin-screw extruder.

In pet food production, the main components of pet food are generally composed of grain meal (such as wheat flour) and animal meal with higher protein content, fresh meat and fat. In the process of pet feed production, when the fresh meat content is as high as 20% to 30%, it needs to be mixed and kneaded vigorously during extrusion, which can only be done by a twin-screw extruder. Because the twin-screw rubs and squeezes each other, even in the case of raw materials with high grease, it will not stick together and will not affect the operation of the machine.

The twin-screw extruder adopts the direct-connected frequency conversion motor drive mode. The spindle speed can be adjusted according to the needs of the processed products. In the state of non-stop and without changing the screw parameter settings, the product varieties can be changed. Its operation is particularly convenient.

2.Advantages of twin screw extruder

The raw material has a wider adaptability and can be adapted to high viscosity, low viscosity, high oil content, high moisture or viscous, oily raw materials.

There are fewer restrictions on the particle size of the raw materials, and it can adapt to raw materials from micro powder to coarse powder particles.

The material is uniform in the barrel, and steam, water, etc. can be added to make the product achieve the desired effect.

The internal and external quality of the product is good, it can achieve a very good homogeneous state and make the molecular structure of the material evenly arranged, the surface is smooth during the extrusion process, and the product particle has high uniformity and good uniformity.

The effect of curing and homogenization is good, the starch curing degree can reach more than 95%, which makes the processed products easy to digest and absorb.

Low production cost, less waste at startup, less waste of water, less man-power, high heat transfer efficiency, high yield and low cost of accessories.