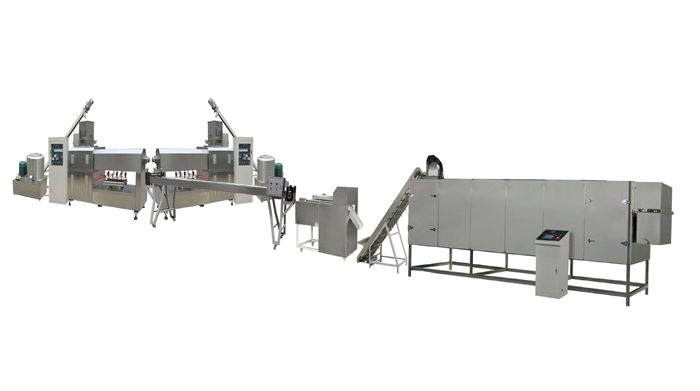

Extruder is a widely used processing equipment, which can be used in the food industry, feed industry, material industry and plastics industry. Jinan Kelid Machinery Co., Ltd. is mainly engaged in Food Extruders, such as for puffed snacks, macaroni, breakfast cereals, vegetable protein, artificial rice, etc.; Feed Extruders, such as for cat food, dog food, fish feed, etc.; Material Extruder, such as for modified starch.

1.Introduction to the extruder structure, and function of each part

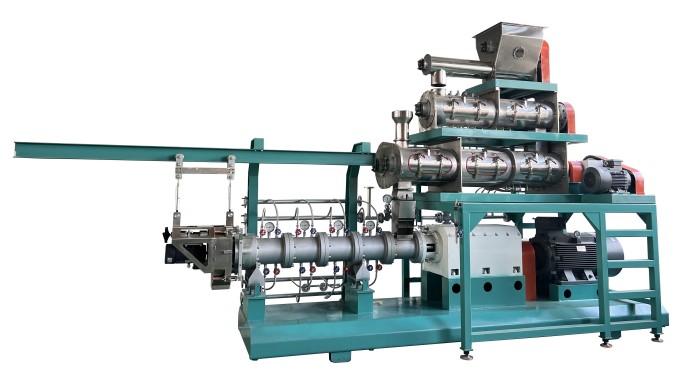

The extruder is mainly composed of Driving System, Transmission system, Feeding System, Extrusion System, Temperature Control System, Cutting System, Shaping System, and Control System.

Driving System. The operation of the main motor generates the driving force to drive the extrusion system to run;

Transmission system. The driving force is distributed to the extrusion system through the transmission system;

Feeding System. Supply raw materials to the extrusion system uniformly;

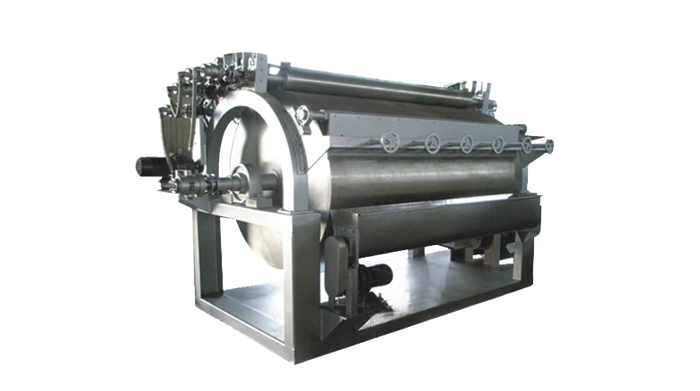

Extrusion System. The core part of the extruder consists of barrel and screw. The raw material is transformed from the original form to the preliminary product form through the extrusion system;

Temperature Control System. Provide active cooling and additional heating for the extrusion system to meet the processing temperature requirements of different products;

Shaping System. Shape the product into different shapes and sizes;

Cutting System. Cut the product into different sizes;

Control System. It is used to control the whole extruder, monitor the operation of the extruder, control the start and stop of each system of the extruder, and also adjust the operating parameters of the extruder.

2.Introduction to the working principle of the extruder

The main motor generates driving force, which is distributed to the Extrusion System through the Transmission System and drives the screw in the barrel to run. The raw material is evenly fed into the barrel of the Extrusion System through the feeding system and is subjected to strong effects of extrusion, friction, shearing, heating, etc., which changes its organizational structure and raw material characteristics, and the basic shape changes from powder to paste. The starch is gelatinized, the protein is denatured, the pathogenic bacteria are killed, the hygienic index is improved, and the toxic components are inactivated. After that, under the action of the Shaping System and the Cutting System, the raw material is transformed from the original form to the product form of different shapes and sizes.